- Jiyang Industrial Park#15, Jinan, China

- info@xyzlift.com

- +86-18366130656

Superior Quality Beyond Competitors

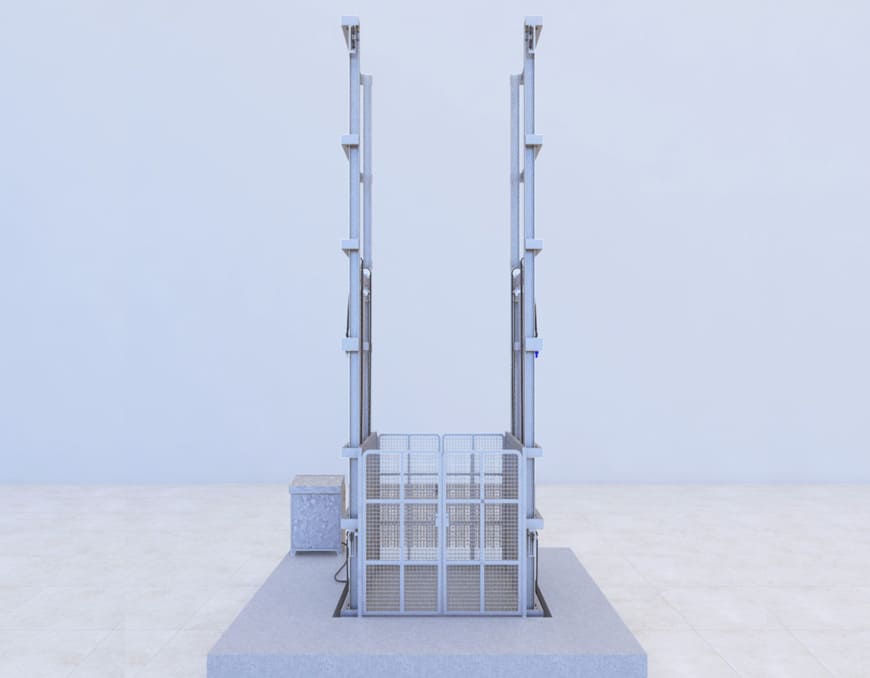

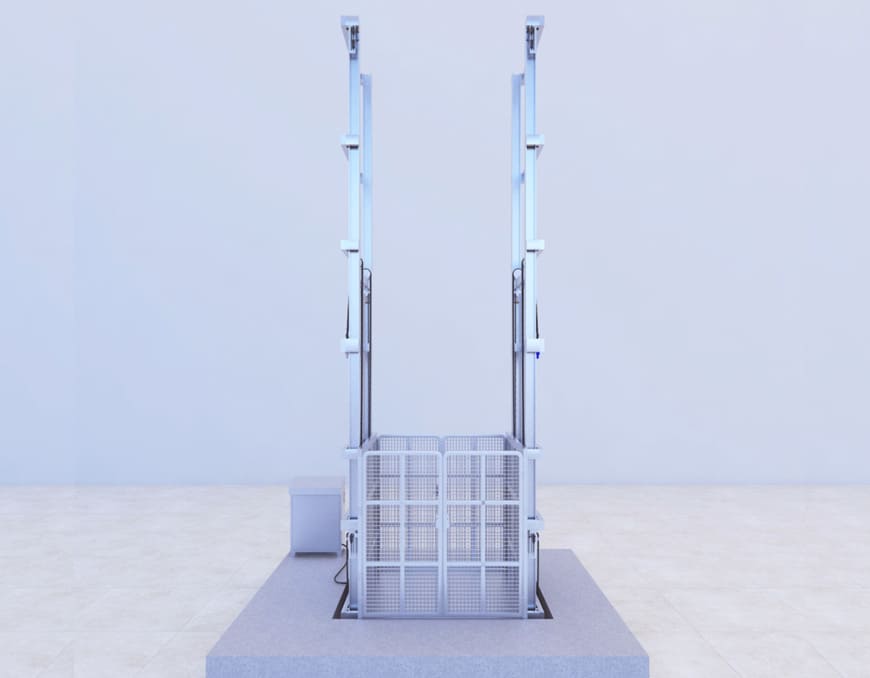

Also referred to as a freight elevator, cargo lift, warehouse lift, or mezzanine lift, the goods lift excels in vertical transportation between different floors. As a leading manufacturer of hydraulic goods lifts, XYZLIFT specialize in customizing lifts to meet unique customer requirements. With our expertise, we offer a wide range of options, including:

Our team of experts collaborates closely with clients, ensuring that each cargo lift is meticulously designed, manufactured, and tested for safety and reliability. We prioritize delivering high-quality products that withstand demanding conditions.

Find the Perfect Goods Lift for Your Business Needs

5 Customized Goods Lift with Special Surface Treatment or Functions

We could still help! Contact our team to find out more.

| Model List | Load Capacity | Lifting height | Platform Size |

|---|---|---|---|

| XYZGL1-2.7 | 1000KG | 2700MM | 1600*1600MM |

| XYZGL1-3 | 1000KG | 3000MM | 2000*1500MM |

| XYZGL2-3 | 2000KG | 3000MM | 2500*2500MM |

| XYZGL3-3 | 3000KG | 3000MM | 2800*3000MM |

| XYZGL5-7 | 5000KG | 7000MM | 4000*35000MM |

| Customsized | Tell us your parameters |

Guide Rail

1 of 7 2Platform

2 of 7 3Hydraulic Cylinder

3 of 7 4Power Pack

4 of 7 5Control Panel

5 of 7 6Limit Switch

6 of 7 7Lifting system

7 of 7The goods lift guide rails are sourced from iron factories that comply with national standards. The thickness and hardness of the H-beams meet the required standards, ensuring goods lift quality.

The framework of the goods lift platform is designed based on the load capacity, with an anti-slip pattern plate on top. The platform is equipped with a 1.2m high guardrail to protect the goods.

The hydraulic cylinder used in the goods lift is specifically designed for hydraulic lifts. It features NSK seals from Japan.The cylinder is also equipped with an explosion-proof valve for added safety.

The hydraulic power unit of the goods lift is supplied by Siemens, known for its long lifespan and minimal maintenance requirements. It can be customized to customer's voltage.

Each floor is equipped with a control panel featuring a emergency stop button. The electrical components used are sourced from Schneider, ensuring reliable performance and safety.

We utilize Omron limit switches in our goods lifts, ensuring accurate and reliable floor-level detection. We incorporate an additional final limit switch at the top floor as an extra safety precaution.

The lifting system of our lifts utilizes galvanized bear and wheel components, ensuring long-lasting durability and resistance to rust. This design ensures smooth and uninterrupted lifting operations.

We adhere to the EN81-31 and national Chinese elevator industry standards, with quality management in line with ISO9001, to provide users with a safer goods lift

You may have challenging issues before the purchase or during the use of a lift. Check our add-on equipment solutions in video and photos.

For large platforms and heavely load goods lift, it is recommended to install this device to effectively prevent the lift from sinking or rebounding when it is reaching a level surface.

Installing landing safety fences on each floor, especially on upper floors, can prevent people from getting too close, making mistakes, falling, and other risks.

Meeting High-End Customer Demands with SEW Motors, Customized Electrical Cabinets, and Wire Color Preferences.

Installed in pit

Ramp instead of pit

Floor Hole

On The Wall

In The Shaft

On The Mezzanine

Step 1 Platform positioning

Step 2 Connect guide rails with the platform

Step 3 Pump station installation

Step 4 Controller box

Step 5 Mesh cover

Step 6 Reinforce to the wall

If you encounter any problems while using our goods lift, our experienced after-sales team will assist you in resolving them quickly.

Safety instructions posted next to goods lift control buttons for secure machine operation.

before operate goods lift, ready operation giuideline to operate goods lift on right way

We provide a detailed daily maintenance checklist to ensure proper upkeep of the goods lift.

Taking a 2-story goods lift with a 3m lifting height and a platform size of 1.2m x 1.2m as an example, the EXW price is around USD4000. The price is subject to fluctuations in the cost of raw materials, changes in exchange rates, and variations in the brand of accessories and add-on equipment.

The delivery time for our goods lifts is 3–5 weeks from the order deposit.

To accurately specify a goods lift, we require the following information:Load capacity: Weight and type of materials to be lifted

Platform size: Size slightly larger than the materials being lifted or shaft size

Travel height: Distance between floors

Loading and unloading directions: Access from one side, opposite sides, or three sides

Special functions or requests: Higher speed, explosion-proof standards, weighing capabilities, specific surface treatments

Additional equipment: Optional items required, such as full mesh cover, electromagnetic fall protection, landing safety fence, roller door, etc.

Our goods lift can travel up to 22m, covering 7 floors.

Our heavy-duty goods lift can lift items weighing up to 100 tons, ensuring stability with thick steel and balance ropes.

Please provide the interested RAL color number, and we will produce the goods lift accordingly.

You will get accurate lift solution in 24 hours.Please supply main information as follows

© 2023 COPYRIGHT JINAN XYZTECH MACHINARY CO., LTD. | COMPANY REGISTRATION NO. 91370100MA3N4C4B39. | ALL RIGHTS RESERVED

We will contact you within 1 working day, please pay attention to the email info@xyzlift.com

Or contact us by whatsapp +86-18366130656

Daily inspection is effective to find the malfunction or fault on the goods lift. Before operation, check the lift according to the following points.

CAUTION! Do not use the goods lift if any malfunction or fault is found.

| Inspection Contents | Standard |

| Every 1 month | |

| Lubricate all the joints and pivot points | Keep lubricated |

| Limit switch for all floors | Running normally |

| Guard-lock switch for landing door | Running normally |

| Guard-lock switch for platform door | Running normally |

| Motor pump station | Running normally |

| Warning light | Running normally |

| Control cabinet terminals | No looseness, no damage |

| Chains | No looseness, no damage |

| Wire ropes | No looseness, no damage |

| Guide rails | No deformation |

| Guard net | No damage |

| All electric wires | No damage |

| Accompanying cable | No damage |

| Every 6 months | |

| Check oil level of oil tank | Keep clean and no oil leakage |

| Check the cleanliness of oil filter | Keep clean |

| Fasten all the connecting parts again | Fastened tightly |

| Check wear and tear of pressure oil pipes | Replace new one if badly worn |

| Check hydraulic cylinder | Keep no oil leakage |

| Fix main parts tighten again | Fastened tightly |

| Check the function of micro-switches | Running normally |

| Check whole working state of the lift | Running normally |

| Every 1 year | |

| Check wear and tear of all axial bushes | No damage |

| Replace hydraulic oil | Accumulated working 1000 hours |

| Check oil leaking | No oil leakage |